Here is a term paper on ‘Biotechnology’. Find paragraphs, long and short term papers on ‘Biotechnology’ especially written for school and college students.

Term Paper on Biotechnology

Term Paper Contents:

- Term Paper on the History of Biotechnology

- Term Paper on the Important Events in Biotechnology

- Term Paper on the Application of Biotechnology in Food Industry

- Term Paper on the Role of Biotechnology in Quality Control

- Term Paper on Marketing of Biotech Products

Term Paper # 1. History of Biotechnology:

Biotechnology is the cutting edge technology and applied science involving use of living cells and cell products and manipulation of genes. Usage of cells and cell products give us the pharmaceutical, diagnostic, agricultural, environmental and other products. Manipulations of genes improve them in some ways to benefit the society.

Therefore, biotechnology can be broadly defined as: “Using living organisms or their products for commercial purposes.”

As such biotechnology has been practiced by human society since the beginning of recorded history in such activities as baking bread, brewing alcoholic beverages or breeding food crops or domestic animals.

The process of agriculture and domestication of animals has been recorded way back to roughly, 1000 years ago. From the very beginning the process of developing better breeds had also been practiced.

In the Indian history we find the mention of “somarasa” in Vedas and Upanishads which is obtained from a plant called “Soma”. This shows that people knew the method of brewing alcohol from various sources. Use of wines and beers had been reported by the ancient people as they knew the method of brewing and fermentation.

Babylonians, Sumerians, Egyptians have been found to practice the process of fermentation to prepare alcohol, vinegar and even acquired gas (mainly carbon dioxide) from different sources. Yeast was used for producing wine and beer while bacteria were used to produce yoghurt.

Many evidences of preparation of pickles and such eatables also have been found in different areas all over the world. The Indus Valley and Indo-Aryan civilizations practiced biotech to produce fermented foods, medicines and to keep the environment clean.

Egyptians used to mummify the dead for preservation and conservation of the dead body.

Crop rotation had been reported by the Greek quite earlier to get better and more crops from the same land.

Baking of cake and bread was practiced by the people of Middle East (i.e., Italy, Turkey and Palestine).

Louis Pasteur who started the pasteurization of milk and identified the role of micro-organisms for fermentation is supposed to be Father of Biotechnology, although the term Biotechnology was given by Karl Erekey in 1917. Clain Weizmann used Clostridium acitobutylicum to convert starch into butanol and acetone. Acetone was an essential part of the explosives used during World War I.

Penicillin was first antibiotic to be discovered by A. Fleming from Penicillium notatum.

Biotechnology was revolutionised during the 1970s to 1980s when the genetic constitutions of the organisms came into knowledge. The base of genetic engineering was laid down by Cohen and Boyer who were able to introduce the desired genes from one organism to the other.

Combination of desired genes into the organism for various purposes is called the recombinant DN A technology which further improved the genetic engineering. European Federation of Biotechnology (EFB) has also contributed in defining biotechnology.

Term Paper # 2. Important Events in Biotechnology:

8000 BC – humans began to domesticate animals and crops and potatoes were cultivated as a means of food.

4000 to 2000 BC — biotechnology was first introduced during this period when the Egyptians began fermenting beer and baking bread. Wine was fermented and the production of cheese began in Sumeria, China and Egypt.

500 BC – the first ever antibiotic which was mouldy soybean curdle, was used in the treatment of a boil in China.

AD 100 — powdered chrysanthemums were used as the first form of insecticide in China.

1322 — artificial insemination is first used to produce superior horses in Arabia.

1590 — the microscope is introduced by Janssen.

1663 — the first cell is recognized by Hooke.

1675 — bacteria is first recognized by Leeuwenhoek.

1761 — successful cross breeding of crops is first accomplished.

1797 — the first child is inoculated with a viral vaccine against smallpox.

1830 to 1833 — the first protein is discovered and the first enzyme is discovered and isolated.

1835 to 1855 — Schleiden and Schwann announce that all organisms are composed of cells and that every cell arises from a cell. 1857 — Pasteur finds that microbes cause fermentation.

1859 — the theory of evolution is published by Charles Darwin.

1865 — Mendel studies garden peas and found that genetic traits are passed from parents to offspring.

1870 to 1890 — plant breeders crossbreed cotton developing varieties with far superior qualities, fields are inoculated to improve their yield, the first experimental corn hybrids are grown in the laboratory, a technique for staining and identifying bacteria is found, the first centrifuge is developed, chromatin is discovered.

1900 — fruit flies are used in early studies of genes.

1906 — the term genetics is used for the first time.

1911 — the first virus which causes cancer is discovered.

1914 — bacteria is first used to treat sewage in England.

1919 — the word biotechnology is first used in print.

1928 — penicillin is first discovered as an antibiotic.

1941 — the term genetic engineering is first used.

1944 — it is proven that DNA carries genetic information.

1951 — artificial insemination of livestock using frozen semen is carried out.

1961 — the first bio pesticide is registered.

1965 — the first human cells are fused with those of a mouse.

1966 — scientists crack the genetic code.

1967 — the first automatic protein sequencer is perfected.

1977 — the first expression of human genes in bacteria is found.

1979 — human growth hormone is first synthesised.

1984 — DNA finger printing is first developed.

1986 — the first anti-cancer drug interferon is released.

1987 — approval is given for the field test of modified food plants, tomatoes that are resistant to viruses.

1988 — Harvard geneticists are awarded patent for the first genetically altered animal, a mouse.

1990 — the first transgenic dairy cow is created to produce human milk proteins for infant formula.

1992 — a technique for testing human embryos in vitro for genetic abnormalities is unveiled by British and American scientists.

1994 — the first gene for breast cancer is discovered.

1995 — the first baboon to human bone marrow transplant is performed.

1996 — a gene associated with Parkinson’s disease is discovered which provides new research into the disease.

1997 — the first animal is cloned from an adult cell and becomes known as Dolly the sheep.

2002 — researchers announce a breakthrough with a vaccine against cervical cancer.

2004 — the FDA approves the first anti-angiogenic drug for cancer and the first cloned pet, a kitten is delivered to the owner.

Term Paper # 3. Application of Biotechnology in Food Industry:

Fermented Foods:

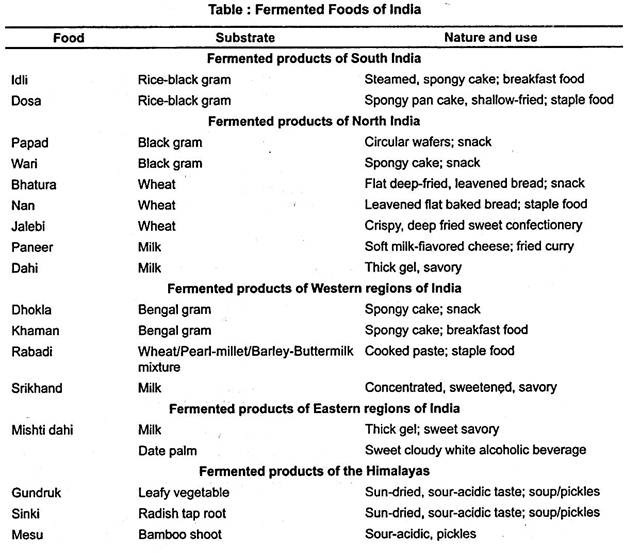

The Biotechnology begins at home, in the kitchen, while preparing various foods and eatables. Various milk products are prepared by fermentation of milk by using micro-organisms.

Fermentation was first aided by the development of the apparatus such as barometer and air pumps. Joseph Black reported that when magnesium carbonate was heated or when limestone was treated with acid, a gas is liberated which is readily absorbed by quick lime in water. It turned to a milky precipitate.

Further it was found that lime water turned milky by the gas released from fermentation. Henry Cavendish performed an experiment to show that all the gas discharged during fermentation (when brown sugar in water was treated with yeast) was absorbed by aqueous sodium hydroxide and had all the properties similar to the one obtained from treatment of limestone with acid.

Antoine Lavoisier provided the chemical basis for the nature of alcoholic fermentation by using analytical techniques for the quantitative estimation of carbon.

Nicolas Appert, a French confectioner who distilled spirits and food products gave methods for preserving foods by putting them into tightly closed vessels that were later on heated in boiling water. This was actually the beginning of the canning industry.

Gay Lussac came to a conclusion that those vessels lacked oxygen. This made another conclusion that oxygen is required for fermentation. Charles Bernard Astier said that air is the vehicle of every kind of germs and is the source of ferment that lives and nourishes itself at the expense of sugar whereby resulting in disruption of equilibrium among the elementary units of sugar. Charles Cagniard – Latour in 1838 described brewer’s yeast as spherical particles that multiply by budding.

On the basis of following points it was proved that yeast is the cause of fermentation:

(i) Its constant occurrence in fermentation.

(ii) Fermentation ceases when boiled, addition of arsenate or other conditions which kill fungus.

(iii) The base material for fermentation must be the one that is evoked and increased by the process itself, which can only be a living organism.

In 1857, Louis Pasteur published his first report on formation of lactic acid from sugar through fermentation.

1. Cultured Butter Milk:

It is a fermented milk product. For its production, starter cultures of Streptococcus lactis or combination of Streptococcus cremories and Leuconostoc citrovorum are added to bulk of pasteurized milk. Lactose is fermented to lactic acid and acetic acid and other organic products, causing the milk to sour.

2. Yoghurt:

It is formed by concentrating the milk to custard like consistency by boiling or adding powdered milk. The bacteria, Lactobacillus bulgaricus and Streptococcus thermophilus are added as starters. Milk sours due to lactic acid formation.

3. Cheese:

It is the most important dairy product which is produced from the milk protein casein. First of all, casein changes to curd by the acid produced by Streptococcus. This may be enhanced by adding an enzyme, rennin (usually obtained from the lining of stomach of calf). The acid curd is separated from the whey.

The whey is used to make processed cheese. The curd is basically an unripened cheese, which is sold as cream cheese or cottage cheese. The ripened cheese is prepared by washing the milk curd and pressing it and cutting the same in desired shapes. They may be salted. Ripening of cheese is done by various microorganisms.

Hard cheese is prepared by inoculation of bacteria:

Streptococcus and Lactobacilli kept at about 15°C for various months. During this time the acids produced give the cheese a unique aroma and taste. Soft cheese is produced by rubbing bacteria and yeast on the outer surface. These organisms digest the protein caesin.

Roquefort, which is also called blue cheese, is made by adding spores of Penicillium in curd.

Other Food Products by Fermentation:

1. Saukeraut:

It is a fermented and preserved form of cabbage. The shredded cabbage is mixed with salt and packed anaerobically. High salt concentration promotes leakage of sugars from the cabbage and reduces water activity obtained. Growth of lactic acid bacteria increases, decreasing the pH. At such a low pH the purifying bacteria cannot grow. Saukeraut it widely used in Western countries. In India we have the examples of various pickles which undergo fermentation and preservation.

2. Bread:

Making the bread from the dough is a very old method employed by the Egyptians way back to 3000 BC. Bread is a fermented product of cereal flours like wheat and rye. The flour is mixed with water, salt, sugar, fat, etc., and is kept for fermentation by yeast, Saccharomyces cerevisiae. During the process of fermentation ethanol and carbon dioxide are formed.

Ethanol either gets evaporated or forms esters. Carbon dioxide is entrapped in dough and leads to expansion of dough which is due to an elastic protein called gluten. Gluten retains the shape of the bread. The flavour and texture of this bread is much better than that produced by the use of baking powder which also produces carbon dioxide.

3. Alcoholic Beverages:

For the production of alcoholic beverages yeast (Saccharomyces cerevisiae) is very common microbe which is used all over the world. Yeast is capable of converting simple sugars into ethanol. It can grow and tolerate the high concentration of alcohol.

In 1861, Louis Pasteur suggested that in the absence of oxygen, yeast consumes more glucose than in the presence of oxygen (anaerobic respiration). During this process the energy produced is much less (i.e., 2 ATPs) as compared to that in presence of oxygen (i.e. 38 ATPs). This phenomenon is known as Pasteur Effect. This effect is used in production of alcohol while the yeast is cultured in the aerobic condition by using aerated broth.

For the production of alcohol various other required substances are:

(a) Sugary materials like fruit juice (or fruit pulp), plant sap and honey.

(b) Starchy materials like various grains and roots.

First of all these starchy materials are subjected to hydrolysis to form fermentable sugars. This process is known as saccharification.

This process of saccharification is carried out either by plant material (barley malt, rye malt or millet malt) or micro-organism which is rich in hydrolytic enzymes.

Process of Fermentation:

Under ideal conditions alcohol production ranges from 2% to 16%.These after proper processing are ready to be drunk, e.g., beers. For the production of beverages of high alcoholic concentration (brandy, whisky, rum, gin, etc.) distillation is also carried out. Production of malt beverages is also known as brewing. The finished products in brewing, i.e., alcoholic beverages differ from the other fermented products not only due to alcoholic content but also due to flavour, aroma, colour, clarity, foam production, stability and satiety.

Production of Beer:

Beer is an undistilled alcoholic beverage in which alcohol content is quite less and ranges between 4-8%. It is produced by fermentation of barley or other cereals, by using S. cerevisiae.

To enhance the fermentation, few adjuncts like wheat, maize, etc. which is rich in starch are also added.

Steps involved in its production are:

(a) Malting:

Dried barley are cleaned and soaked in water for a period of two days. Excess water is removed and then incubated for germination for 4-6 days. The process of germination forms the enzyme amylase and protease for hydrolysis of starch and protein respectively. Temperature is then increased to about 80°C to stop germination, but the enzymes remain in the active form. Malt is then prepared by powdering the seeds.

(b) Mashing:

The powdered malt is mixed with hot water (55-65°C). This mashing of malt separates the soluble materials and adjuncts from malt. It also leads to degradation of starch by amylase to produce maltose, dextrin and glucose and proteins by proteases to produce peptones, peptides and amino acids. The end of mashing results into a medium for fermentation called beer wort.

The dried female flowers of hop plant are added which provide flavour, specific aroma and stabilizing effect to the beer.

(c) Fermentation:

Beer wort is now inoculated with yeast in open or closed fermentors. It is carried out at the temperature of 20-28°C for 5-10 days.

(d) Maturation:

Fermented fluid is transferred to storage tanks maintained at the temperature range of 0-3°C. Storage period is roughly for a few weeks, during which sedimentation of yeast cells and precipitation of nitrogenous substances, resins, phosphates, etc., occurs. The partially matured beer is then subjected to chillproofing which involves the removal of residual proteins (beer is turbid due to their presence). Carbonation of beer is usually carried out by injecting carbon dioxide. Now the matured and carbonated beer is bottled or canned and then pasteurized at 60% for about 20 minutes.

Production of Wine:

Wines:

Large scale production of wines is carried out by using grapes. Grape juice is rich in sugar and other materials along with natural acidity. Grapes are crushed mechanically to extract the juice. The juice which is now ready for fermentation is called must. Sulphur dioxide is added to inhibit the growth of unwanted microbes but can be tolerated by wine fermenting yeasts.

Oxygen is bubbled through the fermentation medium to promote good growth of yeast, slowly aerobic condition is established. Production of wine takes 2-5 days. After fermentation wine is transferred to storage tanks called vats. Now wine is subjected to ageing which takes some months or years. Ageing develops specific flavour and aroma. It contains 14-16% alcohol.

Fermentor or Bioreactor:

It is a specially designed vessel used for large scale production of the products. Several biological reactions (oxidation-reduction-reaction) take place in the cells of organisms inoculated in it and therefore it is also called bioreactor. As per the requirement the environmental condition in the fermentor can be changed and maintained.

Traditional fermentors are open vats made up of wood or slate. Modern fermentors are made up of stainless steel. A high quality stainless steel does not corrode or lose toxic metals into the growth medium. The size of a bioreactor also varies from 20 litres-250 million litres. The bioreactor may be an open or closed vessel.

Some important fermentors with some special features are as follows:

(a) Stirred Tank Reactor:

It has arrangement for proper mixing by agitation using impeller and maintaining a uniform environment.

(b) Bubble Column Reactor:

As the name indicates, it produces bubbles using spargers for mixing the fluids.

(c) Airlift Reactor:

It uses mechanical device for mixing.

The preparation of fermentor for the next fermentation is called turned around. The time taken in this preparation is called down time, which is non-productive and should be kept as short as possible. The preparation involves cleaning of fermentor which is done by using high pressure water jets fixed into the fermentor.

Unit Operation:

Unit operations are the steps taken within the process to change or separate the components during a bioprocess.

Some steps are:

(i) Centrifugation:

It is used to separate solids from liquids.

(ii) Chromatography:

Separation of molecules based on size.

(iii) Cooling.

(iv) Crystallography:

It is to form crystals, for separation and identification of bio products.

(v) Dialysis:

It is for removal of impurities.

(vi) Distillation.

(vii) Drying:

It is for removal of solvent.

(viii) Evaporation:

It is for removal of solvent.

(ix) Filtration:

It is for separation and purification of chemicals using filters.

(x) Heating.

(xi) Humidification:

It is the addition of water.

(xii) Membrane Separation:

It is the separation of liquid from solution.

(xiii) Milling:

It is the process of grinding the material.

(xiv) Precipitation.

(xv) Solid handling.

(xvi) Solvent extraction.

Term Paper # 4. Role of Biotechnology in Quality Control:

Scale-Up:

In general, fermentation/bio processes techniques are developed in stages, starting from a laboratory and finally leading to an industry. The phenomenon of developing industrial fermentation process in stages is referred to as scale-up. Scale-up is necessary for implementing a new fermentation technique developed by using mutant organisms.

The need of scale-up is to develop optimal environmental and operating conditions of different levels for a successful fermentation, substrate concentration, agitation and mixing, aeration, power consumption and rate of oxygen-transfer.

In a conventional scale-up, a fermentation technique is developed in 3-4 stages (i.e., scales). The initial stage involves a screening process using petri dishes or Erlenmeyer flasks. The next stage is a pilot project to determine the optimal operating conditions for a fermentor with a capacity of 5-200 litres. The final stage involves the transfer of technology developed in the laboratory to industry.

It has to be continuously noted that a fermentation process that works well at the laboratory scale may not work at all on industrial scale. Therefore, it is not always possible to blindly apply the laboratory conditions of a fermentation technique to industry. At the laboratory rate one is interested in maximum yield of the product for unit time.

At the industry level, besides the product yield, minimal operating cost is another important factor for consideration. An industrial biotechnologist has to apply his/her intellect and the technical skill for establishing a successful fermentation set up in a cost- effective manner.

Quality Control in Manufacturing:

The ultimate aim of any good manufacturing process is to bring a product of superior quality in to the market. Therefore, quality control is of great importance in any manufacturing process.

A product has to undergo strict quality control tests and procedures. Quality control ensures that a product is not released for use until its quality has been judged satisfactorily. Quality control is concerned with sampling, specification and testing as well as organizing a separate quality control unit to ensure this, which operates independently. Quality control has to take care of all parameters, which directly or indirectly affect the quality of the product.

The parameters of quality control depend on the type of the final use of the product, e.g., if the product is a therapeutic protein like vaccine or hormone, it should be biologically pure and chemically stable.

So the product is examined for its:

1. Biological activity.

2. Purity, chemical and physical properties.

3. Life and stability.

A few other points to be taken into consideration to successfully incorporate quality control in a manufacturing unit are:

1. The procedure of the manufacturing process should be standardized and should be approved by a research laboratory.

2. Enough trained manpower to carry out manufacturing, sampling, inspecting and testing of the materials at the different stages of the process, e.g., starting materials, intermediates and final products.

3. Proper packing with correct labeling, which include some information about the property and handling procedure.

4. Samples should be taken in approved manner to test its qualities.

5. Records of sampling, inspection and test procedures carried out should be maintained properly and should be made available for inspection by the authorities on demand.

6. The final product should contain the active ingredients complying with the qualitative composition of the state formulation.

7. The product should be certified by a qualified person or by an approved committee before it is released for sale.

8. Sufficient quantity of the starting materials, intermediates and final products should be retained for future examination if required.

9. The packaging should also be of the right type, which would guard the products from any degradation or change. The impact of physical parameters on the property of the products should be recorded on the label.

Term Paper # 5. Marketing of Biotech Products:

Marketing high technology products and innovations like that of biotechnology is much the same as marketing more traditional products and services. The marketing of a familiar product is very different from that of an unfamiliar product. The marketing of biotechnology product is also dependent upon various factors as that of normal products.

Therefore, the normal criteria of marketing are applicable in this case also. Introducing a new product particularly an unconventional product, like that of modern biotechnology is more difficult than making that new product.

In 1995, sales of products derived from recombinant DNA-based technologies approached $ 8 billion, less than 4% of worldwide pharmaceutical sales. Modern biotechnology products started appearing in the market only in the late 1980’s. Now, there are a lot of products of modern biotech available in the national as well international market.

The industry has its own strategies for getting into and competing in the market. New technologies and their demonstration among the consumers (like controlled drug-delivery technologies, targeted drug-delivery technologies, etc., and specialized, more patient-friendly technologies to deliver protein- based drugs) are vital to the future marketing success of protein based drugs and other biotechnology products.

This is because:

1. Proteins are erratically absorbed or are inactivated when swallowed, thus they have to be injected.

2. Proteins are generally unstable and reactive.

3. Most proteins have short life in plasma after injections.

Some of the technologies that could appear in the future markets are the following:

(i) Insulin could be delivered by nasal sprays or orally, self-regulated implants, artificial pancreas with monoclonal insulin-producing cells.

(ii) Protein drug doses could be administered in very small controlled delivery systems over days, months, or even years on a single refilling.

(iii) In case of drug targeting, drug goes only to infected cells. The use of liposomes as drug container or vehicle to carry toxic solution liberating antibodies or surface reactive chemicals will lead to better targeting and tissue-selective delivery system.

New technologies in the production of drugs by biotechnology can reduce the cost of drugs and other products and then it will become more consumers friendly.