In this article we will discuss about:- 1. Definition of Liposome 2. Classification of Liposome 3. Applications 4. Formation 5. Microencapsulation.

Definition of Liposome:

A liposome can be defined as an artificial lipid vesicle that has a bilayer phospholipid arrangement with the head groups oriented towards the interior of the bilayer and the acyl group towards the exterior of the membrane facing water. Liposomes are usually made of phosphatidylcholine (lipid) molecules although mixtures of phospholipids can also be employed to make liposomes.

The main difference between liposomes and cell membranes is the lack of bilayer asymmetry in the case of liposomes. On the other hand, liposomes do exhibit barrier properties very similar to those of cellular lipid membranes, and therefore, they are frequently used as a model system for the study of the transport activity of the cell membrane boundary.

Since the invention of liposomes in the early 1960’s as ‘membrane-like’ structures, they have been extensively used in the biotechnology field. The ‘membrane-like’ characteristics, their colloidal size as well as their solubility properties for various molecules have made liposomes useful tools for various biotechnology applications, from foods applications (such as in enzyme microencapsulation), to fermentation and several medical/pharmaceutical applications.

A few possible mechanisms for liposome absorption into cells are illustrated in Fig 2. Fusion and endocytosis are the most common ones being utilised for the production of liposomes with industrial or medical purposes.

During fusion, the soluble material carried in the liposome is released into the cytoplasm of the target cell through the joining of the liposome with the cell membrane lipids.

Such a mechanism is useful for introducing hydrophobic material into the cell, and it has been already employed by the petroleum industry.

In the case of endocytosis, the liposome enters the cell surrounded by an endocytotic vacuole that is derived from the membrane lipids. The contents of the liposomes are then released by the action of liposomes that were attached to the produced vacuole. Low molecular weight compounds (that are not charged at low pH values) will thus be able to diffuse into the cytoplasm.

Classification of Liposomes:

Liposomes are classified according to their size and structure, the latter also depends on the preparation method. There are three classes of liposomes: multilamellar vesicles (MLV’s), small unilamellar vesicles (SUV’s) and unilamellar vesicles. The type of liposome being utilised in a specific application depends on the hydrophobicity of the molecule being encapsulated.

MLV’s consist of a series of multiple lipid bilayers that are obtained from a phospolipid solution in chloroform, which is then evaporated to produce a thin film and subsequently hydrated in an aqueous solution to form heterogeneous vesicles with diameter sizes from ~0.3 to 2.0 µm.

The main advantage of the MLV’s is that both the lipids arid the aqueous solutions to be encapsulated are not subjected to harsh treatment. The use of high-intensity ultrasonication, ethanol injection and pressure applied to multillamelar vesicles allows the production of single bilayer vesicles SUV’s; this physical treatment reduces the liposome size. Unfortunately, the smaller size of such a vesicle also results in a higher curvature that limits its capture volume.

LUV’s are prepared commonly by infusion, reverse- phase evaporation and detergent dilution methods. They vary in size range from 100-500 nm and they are the most widely employed liposomes because they have less variable size and higher entrapment volumes (>~2.7 L/mol of lipid) than SUV’s. Several techniques may be employed to characterise liposomes. Table 2 compares some of the current techniques and novel approaches to the study of liposomes and their interactions.

Applications of Liposomes:

Lecithin-based liposomes offer great flexibility and shelf life improvements in the food industry for introducing water-soluble substances such as flavours and micronutrients.

Such modified liposomes are also being used at present in the beverage and bakery industries to deliver both flavours and oils that are trapped inside the liposomes; such flavours and oils are released then into the mouth; these are also employed to incorporate flavour oils. The major impact of such techniques has been achieved through the use of microencapsules that can be made through a continuous process on an industrial scale.

In the dairy industry, liposomes containing enzymes have been reported to reduce the ripening time by 30-50%, as well as improve texture and flavour. The latter was caused by a decrease in the action of proteolytic enzymes in the early phases of cheese fermentation.

Because liposomes have the ability to carry fat-based flavours in their bilayer, as well as water-soluble flavours in the core of the vesicle, they protect the flavour from degradation and also increase the longevity of the flavour in the system where they are being employed. Therefore, their use in the beverage industry has become widespread.

The rate of diffusion through/from the bilayer depends on the liposome composition as well as physical properties of the flavour. Bakery is another area where liposomes have been applied and it is based on the characteristic of the liposomes of not being destroyed during the processes of mixing or extrusion; therefore, they can release encapsulated flavorings, fragrances or food additives.

When a flavour is encapsulated, the release occurs after the enzymatic degradation of the liposome, and thus the rate of release depends on the physical properties of the material of which the liposome is made. In the case of lecithin, the pH value or range, as well as temperature, are important factors.

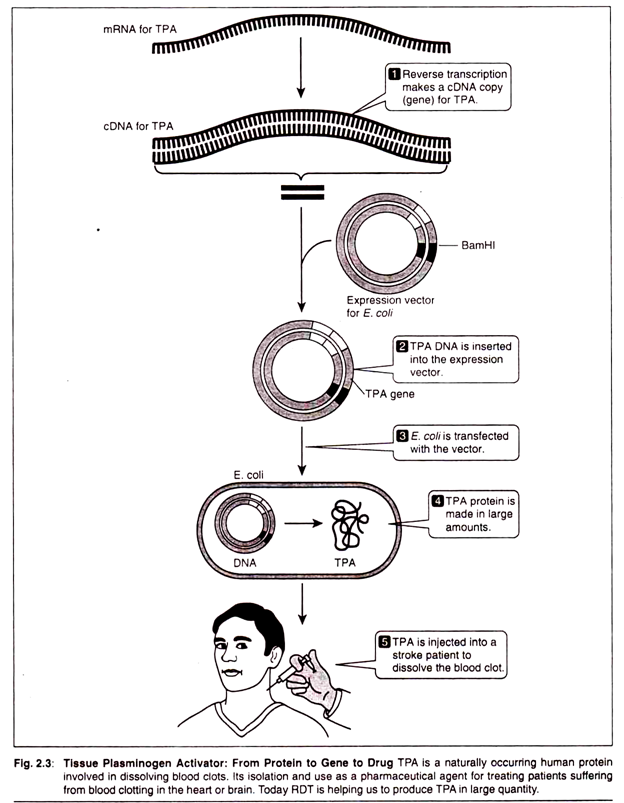

Traditionally, liposomes have been used in the bioengineering field to over-produce certain proteins through the genetic modification of cells. They have thus solved the inconvenience of transferring high molecular weight molecules through cell membranes.

The use of unilamelar vesicules made of cationic lipids has improved the transfection efficiencies and prevented interactions with DNA molecules. Therefore, the project of introducing genes to cure diseases (genetic therapy) is not far from becoming a reality if the patient being treated were found not to suffer from severe side effects.

Vaccine formulations based on liposomes have been successfully tested in animal immunisation, and such studies are currently in the clinical testing phase. The benefits and limitations of liposomes as drug carriers in a system as complex as the human body depend basically on the interactions of liposomes with the cells, as well as their immuno-compatibility, or their ability to escape detection by the human immune system.

Cosmetics are another area where the liposomes have been extensively employed. They are being utilised as humectants, as well as carriers of formulations containing extracts, vitamins, moisturisers, antibiotics and proteins.

Such applications are mostly directed towards preventing, or delaying, the aging of the skin. Through their surfactant action liposomes also improve the coagulation and sinking of oil spreading at a water interface, a methodology which has been under study for some time by EPA for cleaning up oil spills.

Formation of Liposome:

The phase diagram in Figure 3 illustrates the phase changes around the transition temperature (Tc) of a phospholipid-water system. This phase transition temperature is defined as the minimum temperature required for the water to break through the lipid membrane. When the system is cooled to temperatures below Tc, the hydrocarbon chains adopt an ordered packing phase, thus creating a lamellar structure.

In the bilayer structure, the hydrophobic tails are lined up together through hydrophobic interactions, whereas the hydrophilic part of the lipid faces towards the aqueous phase.

Microencapsulation of Liposome:

The lipid-aqueous system needs to meet two major requirements for the liposome microencapsulation to occur. First, the system needs have a negative free energy, and second, it needs to overcome the energy barrier which is necessary for the formation of the bilayer. Three methods of liposome preparation are here -described:

Microfluidisation:

Microencapsulation by this method is obtained through the dynamic interaction of two pressurised aqueous-lipid fluids that create a large momentum and flow turbulence that allows the system to overcome the energy barrier to microcapsule formation.

The pressure applied in air-driven microfluidisers can be as high as 10,000 psi. The ultra-high velocities reached by this technique allow the creation of small liposomes (< ~0.3µm) with high capture efficiency. This system is useful because of its capability to produce very large amounts of liposomes with adjusted size in a continuous process.

Ultrasonication:

The ultrasound absorption is employed to overcome the energy barrier. The sonication of the lipid emulsion can be carried out by two different approaches. The first one is through the use of a sonication probe placed directly into the suspension of liposomes.

The second method is slower than the first one and employs a sonication bath, such as a sealed container filled with Nitrogen or Argon gas. Both methods have been extensively applied for the formation of SUV’s; however, the use of a sonication probe has been found to cause contamination of the liposomes.

Reverse phase evaporation:

Reverse phase evaporation is used for the preparation of LUV’s and it is based upon the extraction of a nonpolar solvent from an aqueous- nonpolar inverted micelle by rotatory evaporation under vacuum. This withdrawal of the nonpolar phase changes the intermediate gel-like phase of the micelle into unilamellar and oligo-lamellar vesicles.

The advantage of this technique is the uniformity of the vesicles formed (from about 0.2 to 1.0 µm) as well as their high encapsulation efficiency. On the other hand, the exposure of the components to organic solvents and sonication is likely to result in protein denaturation.